Factory supplied Progressive Mineral Lens - CONVOX 1.59 SF Semi Finished PC Polycarbonate HMC Optical Lens – CONVOX

Factory supplied Progressive Mineral Lens - CONVOX 1.59 SF Semi Finished PC Polycarbonate HMC Optical Lens – CONVOX Detail:

What Products can we Produce?

Index: 1.499, 1.56,1.60, 1.67, 1.71,1.74, 1.76,1.59 PC Polycarbonate

1.Single Vision Lenses

2. Bifocal/Progressive lenses

3. Photochromic Lenses

4. Blue Cut Lenses

5. Sunglasses/Polarized lenses

6. Rx lenses for single vision, bifocal, freeform progressive

AR treatment: Anti-fog, Anti-Glare, Anti-virus, IR, AR coating color.

Quick Details

| Place of Origin: | Jiangsu, China | Brand Name: | Convox |

| Model Number: | 1.59 SF PC | Lenses Material: | Resin |

| Vision Effect: | Photochromic | Coating: | EMI, HMC |

| Lenses Color: | Clear | Product Name: | 1.59 SF PC POLYCARBONATE HMC |

| Other Name | 1.59 SF PC POLYCARBONATE HMC | Design: | Aspheric |

| Material: | Acrylic | Color: | Clear |

| Multi color: | GREEN | Transmittance: | 98~99% |

| Abrasion Resistance: | 6~8H | HS CODE: | 90015099 |

| Port: | Shanghai |

Production Flow Chart

Semi Finished Lenses

Semi-finished lens is the raw blank used to produce the most individualized RX lens according to thepatient’s prescription. Different prescription powers request for different semi-finished lens types or base curves.

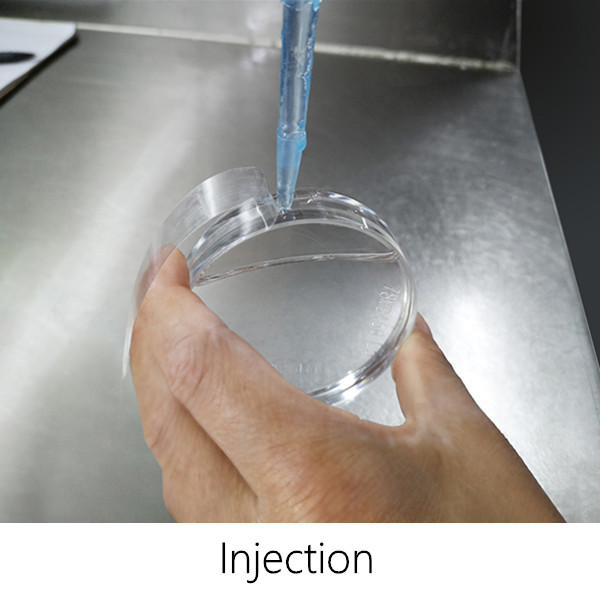

The semi-finished lenses are produced in a casting process. Here, liquid monomers are first poured into moulds. Various substances are added to the monomers, e.g. initiators and UV absorbers. The initiator triggers a chemical reaction that leads to hardening or “curing” of the lens, while the UV absorber increases the UV absorption of the lenses and prevents yellowing.

More

—-Hardness: One of the best quality in hardness and toughness, high impact resistance.

—-Transmittance:One of the highest transmittance as compared with other index lenses.

—-ABBE: One of the highest ABBE value providing the most comfortable visual experience.

—-Consistency: One of the most reliable and consistent lens product physically and optically.

Description

Polycarbonate was developed in the 1970s for aerospace applications, and is currently used for the helmet visors of astronauts and for space shuttle windshields. Eyeglass lenses made of polycarbonate were introduced in the early 1980s in response to a demand for lightweight, impact-resistant lenses.

Since then, polycarbonate lenses have become the standard for safety glasses, sports goggles and children’s eyewear. Because they are less likely to fracture than regular plastic lenses, polycarbonate lenses also are a good choice for rimless eyewear designs where the lenses are attached to the frame components with drill mountings.

Products Show

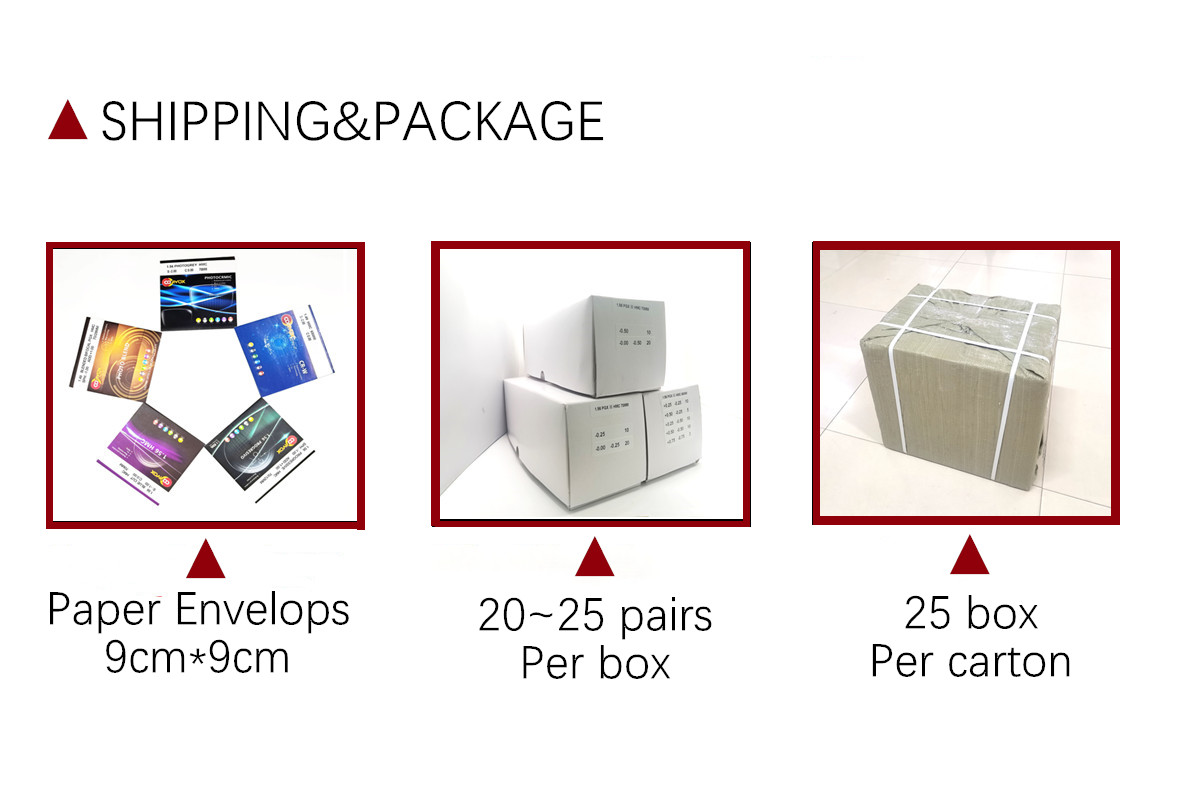

Product Packaging

- Packaging Details1.56 hmc lens packing:

envelops packing (For choice):

1)standard white envelops

2)OEM with customer’s LOGO, have MOQ requirement

cartons: standard cartons:50CM*45CM*33CM(Every carton can include around 500 pairs lens,21KG/CARTON)

Port:SHANGHAI

Shipping & Package

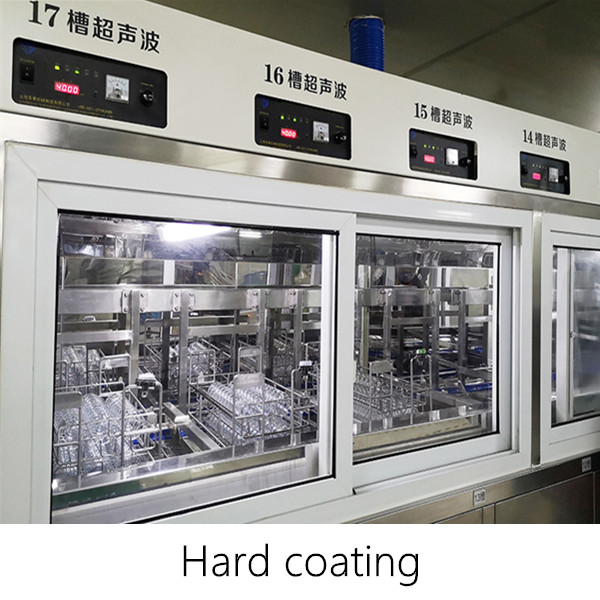

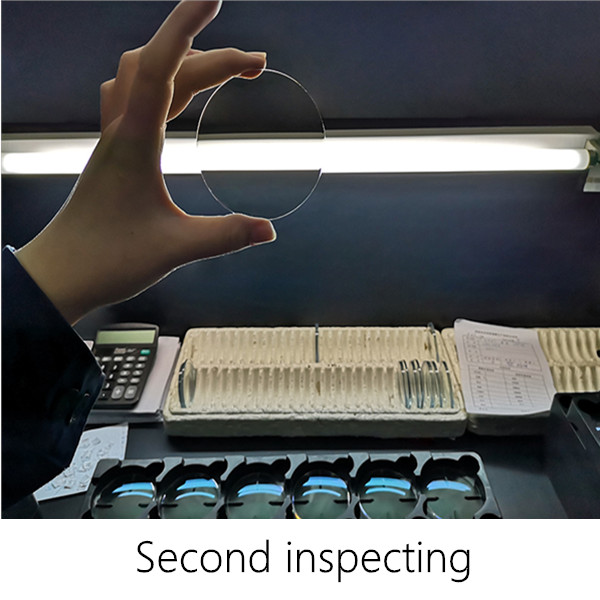

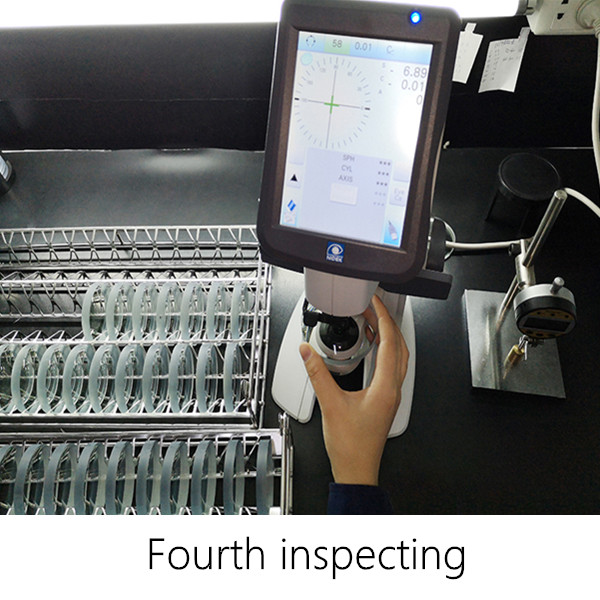

Production Flow Chart

About Us

Certificate

Exhibition

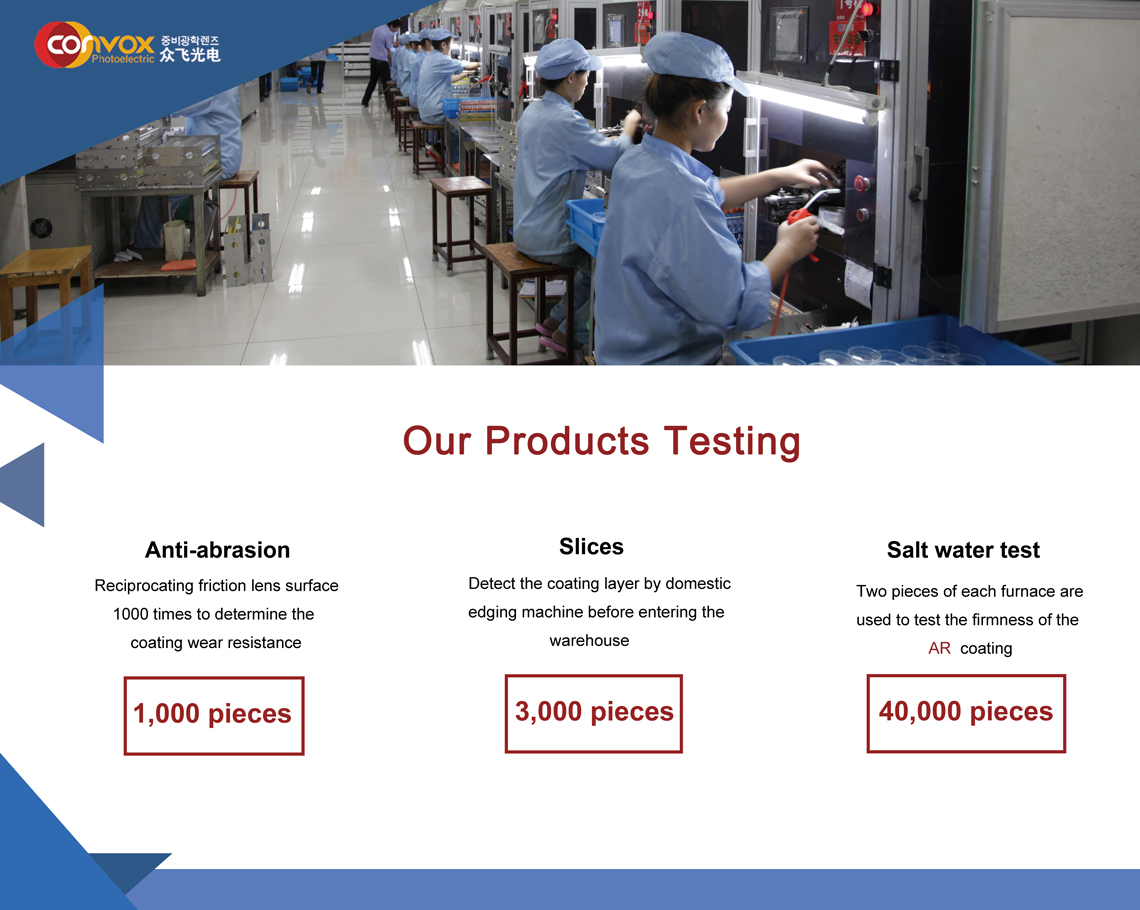

Our Products Testing

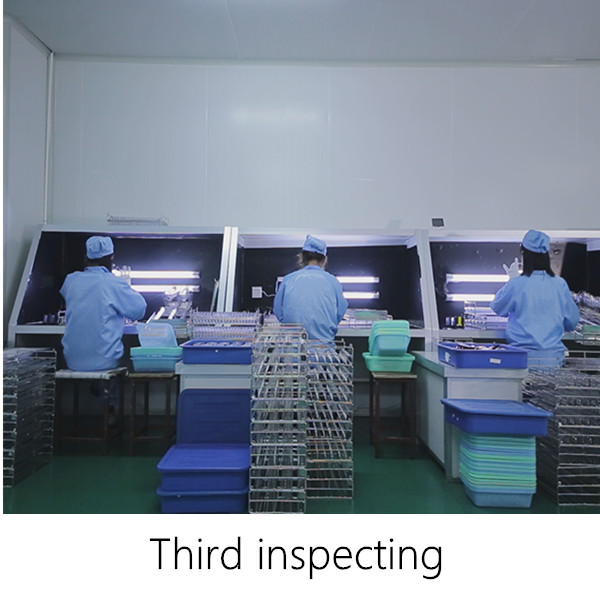

Quality Checking Procedure

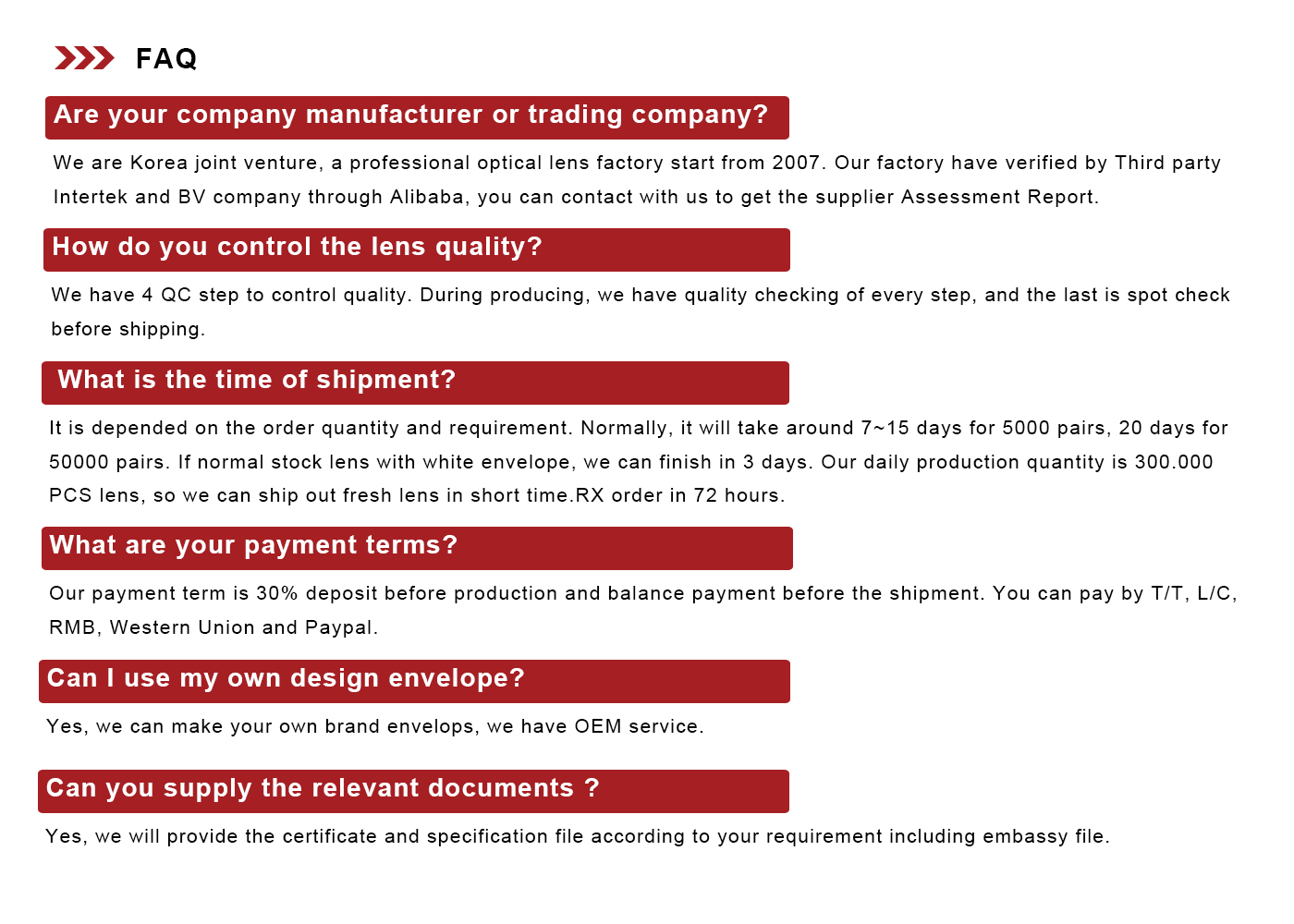

FAQ

Product detail pictures:

Related Product Guide:

We insist on offering premium quality creation with very good company concept, honest product sales along with the finest and fast assistance. it will bring you not only the premium quality item and huge profit, but the most significant is to occupy the endless market for Factory supplied Progressive Mineral Lens - CONVOX 1.59 SF Semi Finished PC Polycarbonate HMC Optical Lens – CONVOX , The product will supply to all over the world, such as: Ecuador, Angola, Netherlands, Many products fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't need to waste time shopping around.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.